Posted 30th August 2025

Posted 5 months ago

By Harry

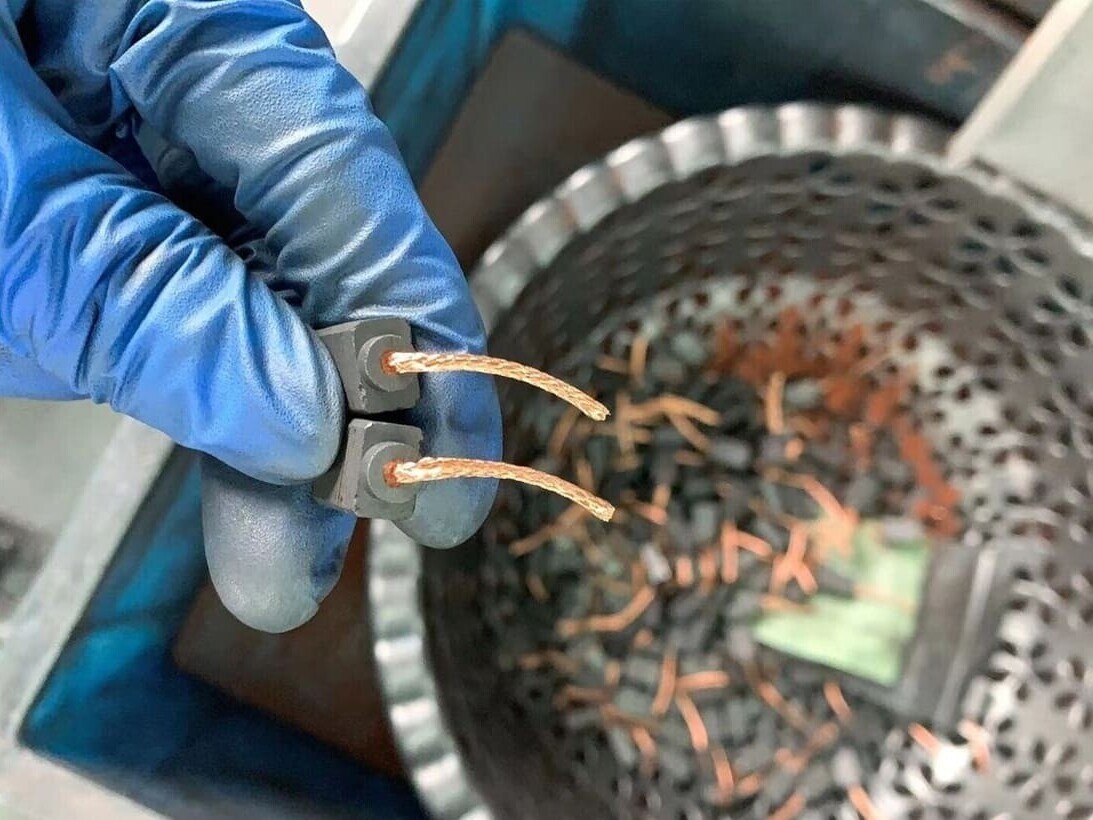

How to change Carbon Brushes on a Dewalt DWE4036-GB Angle Grinder

Locate and change carbon brushes on a Dewalt DWE4036-GB Type 1

Why Choose TDO Carbon for Your Power Tool Brushes?

1. Premium Quality Replacement Brushes: TDO Carbon offers only the highest quality carbon brushes designed to deliver maximum performance. Our brushes are crafted to fit perfectly into your Makita, Bosch, Dewalt, Hitachi, and Evolution tools, ensuring they function like new. We understand that downtime costs you money, which is why we offer reliable, durable brushes that get your tools back in action fast.

2. Boost Your Tool Efficiency: Over time, carbon brushes wear down, causing power loss and even tool failure. Our aftermarket replacement brushes are designed to restore lost power, ensuring that your tools work at their optimal level. Whether you need to replace brushes in a Makita drill, Bosch angle grinder, or Dewalt saw, TDO Carbon has you covered.

3. Extended Tool Lifespan: Replacing worn-out carbon brushes helps extend the lifespan of your tools, saving you from costly repairs or replacements. By choosing TDO Carbon, you’re making an investment in your tools’ longevity. Keep your power tools running smoothly for longer and reduce the need for expensive new equipment.

Locate and change carbon brushes on a Dewalt DWE4036-GB Type 1

How long do carbon brushes last in power tools? Discover the key factors that impact brush life and when it's time for a replacement.

Learn how to change carbon brushes in power tools and keep your tools running like new with this easy guide!

Worried about sparking brushes? Learn how to stop motor brushes from sparking and prevent costly damage.

These things don’t fail instantly—they wear down bit by bit, and if you catch them early, you avoid bigger problems. Here’s how to tell when it’s time for a replacement:

Key Signs of Worn Brushes:

Pro Tip: Diagnose by Sound*

Ever noticed a tool sounding higher-pitched or “scratchy” at high RPMs? That’s often a brush issue. A corded drill spinning at 2,800 RPM* should have a smooth hum—if it starts whining or fluctuating, your brushes might be bouncing inside the holders, causing inconsistent contact.

Plenty of people grab any old replacement that “looks about right” and end up with sparking motors, tools that overheat, or brushes that grind down in weeks. Here’s why material choice matters and how to pick the right type.

A carpenter using a router for precision joinery needs graphite-based brushes to keep friction and sparking low, ensuring smooth speed control. But a metal fabricator grinding thick steel all day with a 9-inch, 2,200W angle grinder needs copper-graphite to handle the high current draw without burning out.

Wrong choice = overheating, rapid wear, or weak power delivery.

Even if you pick the right material, the wrong size or fit can cause:

1. Check the Old Brush – Most have a part number stamped on them. If it’s readable, just match it.

2. Look in the Manual – Manufacturer specs will list the correct size and type.

3. Measure Manually – If there’s no marking, grab a caliper and measure width, thickness, and length. Standard sizes include:

> 6x10x15mm

> 6.4x12.5x22mm

> 8x16x22mm

A brush that’s even 0.5mm too big can get stuck in its holder, stopping proper contact. One that’s too small can bounce around and spark excessively.

Always verify size before buying—"close enough" isn't good enough.

Bargain replacements seem like a steal, but they wear out faster, overheat, or damage your motor.

A builder with a Makita hammer drill grabbed a generic aftermarket brush set online. Within two weeks, the drill started overheating and losing power. The low-density carbon wore out in a month, forcing another replacement.

He switched to a quality brush set from a trusted UK supplier, and the drill ran like new—lasting over a year before needing another swap.

Lesson? Cheap upfront = spending more later.

Swapping them out is straightforward if done right. Rushing it, though, can cause seating issues, overheating, or motor wear.

1. Power Off & Open the Housing – Unplug the tool or remove the battery.

2. Locate the Brush Holders – Usually found on either side of the motor.

3. Remove Old Brushes – Take note of how the springs are positioned.

4. Insert New Ones – Ensure they slide smoothly and aren’t forced in.

5. Bed Them In – Run the tool at low speed for 5-10 minutes to let the brushes seat properly.